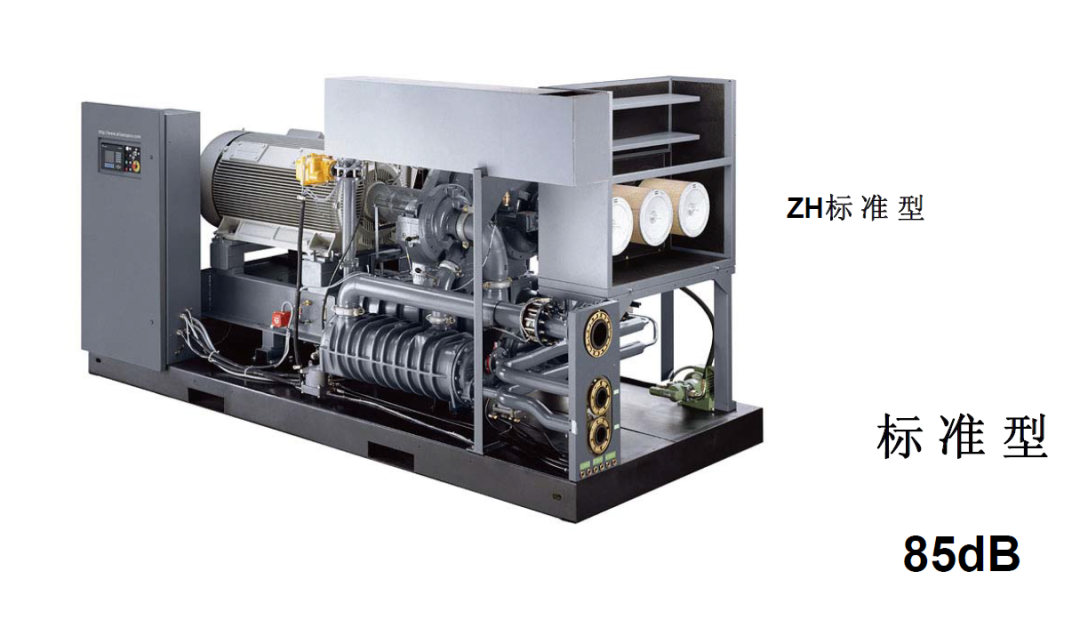

Air separation unit knowledge | About Atlas Copco ZH series centrifugal air compressors

The integrated ZH series centrifugal compressors meet your following requirements:

Higher reliability

Lower energy consumption

Lower maintenance costs

Lower total investment

Extremely easy and low-cost installation

A truly integrated unit

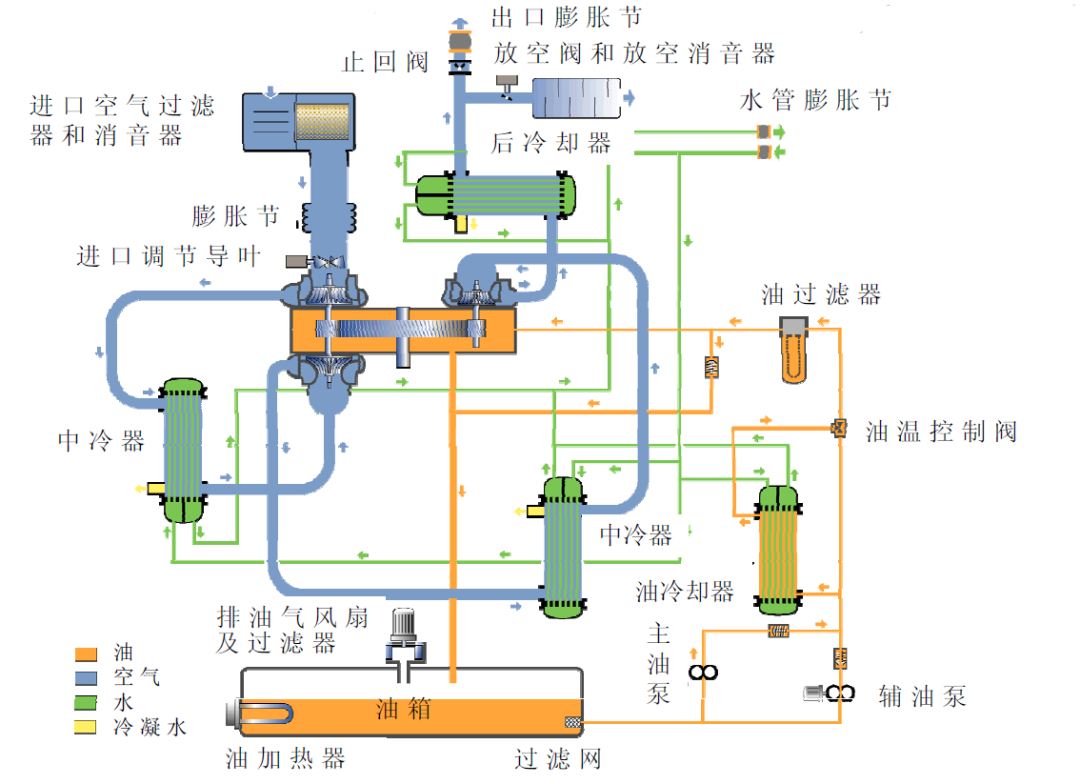

The integrated box unit includes:

1. Imported air filter and silencer

2. Imported adjustment guide vane

3. Aftercooler

4. Venting valve and venting silencer

5. Check valve

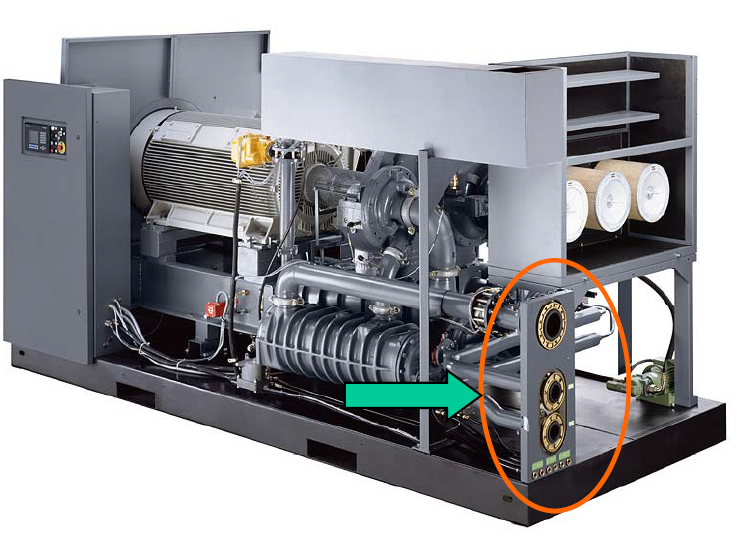

6. Inlet and outlet cooling water main

7. Advanced control and safety system

8. Expansion joints are installed on the exhaust pipe and inlet and outlet pipes

9. All coolers are equipped with water traps and automatic manual drain valves

10. High pressure motor

The integrated unit is ready to use

Connect one exhaust pipe, connect two cooling water pipes, connect a high-voltage power supply, connect a low-voltage power supply and turn it on

The whole machine test has been done

Extremely convenient and low-cost installation

No special foundation required

No need for anchor bolts

Minimal floor space

Clear responsibility

High reliability

Lower total investment

Advantages of integrated compressor design

Greater rigidity, shorter connecting pipes, dynamically optimized design of connections with minimal pressure drop and minimum leakage

High reliability and efficiency

Proper anti-corrosion and silicone-free design

All air path components are coated with special DuPont resin coating, which has excellent corrosion protection.

The air path is completely silicone-free, reflecting a commitment to health and environmental protection, high reliability and low maintenance costs