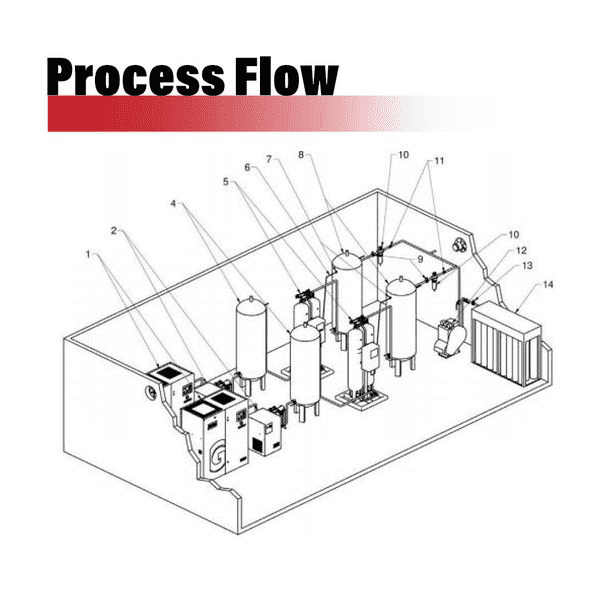

Brand NUZHUO – Working Process Flow of PSA Oxygen Plant

1.Air compressor (screw type): Air is used as raw material to collect & compress air to 8 bar.

2.Refrigerated dryer: The standard configuration removes moisture and impurities in the air, so that the air dew point reaches -20°C (the intermediate configuration uses an adsorption dryer, and the dew point reaches -40°C; the advanced configuration uses a combined dryer, and the dew point reaches- 60℃).

3.Precision Filter: A/T/C three-stage filter to remove oil, dust and impurities.

Air buffer tank: store pure and dry air for subsequent adsorption and separation of oxygen and nitrogen as raw material storage.

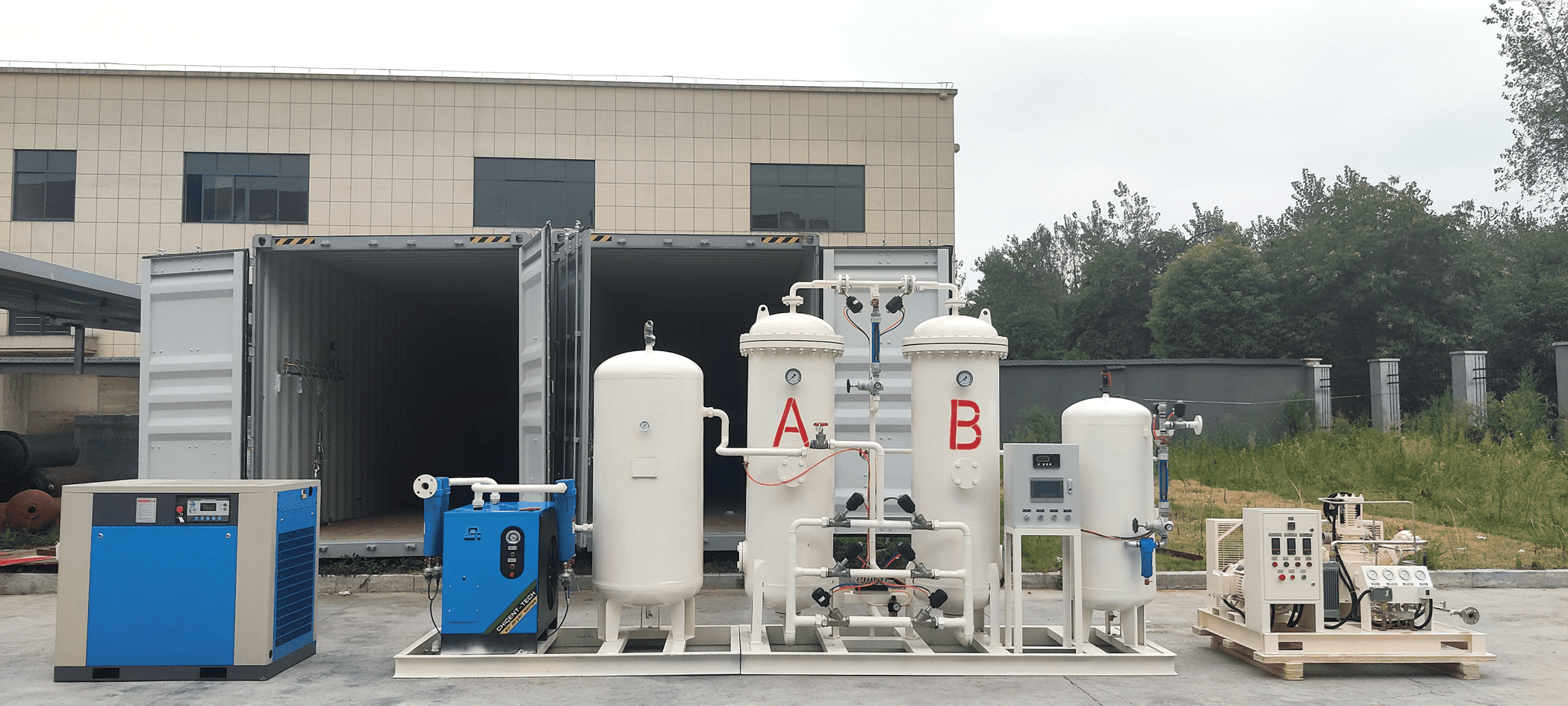

4.Adsorption tower: A&B adsorption tower can work alternately, regenerating adsorption, filling sodium molecular sieve to filter out oxygen molecules.

5.Oxygen & nitrogen analyzer: real-time monitoring and analysis of oxygen & nitrogen purity, indicating that the equipment is working normally and alarming.

6.Valves & pipelines: Intelligent control valves realize automatic operation of equipment, PLC control, SUS304 pipelines.

7.Oxygen & Nitrogen Buffer Tank: Store oxygen & nitrogen with qualified purity, which can be directly piped or used for bottle filling.

8.Pressure regulator: Adjust and temperature the outlet pressure of oxygen & nitrogen (3-6Bar).

9.Dust filter: Remove the dust brought by molecular sieve in oxygen&nitrogen.

10.Check valve: prevent oxygen & nitrogen back flow.

11.Booster: Gas booster, pressurize the oxygen&nitrogen to the filling pressure, generally 150bar or 200bar.

12.Pressure regulating valve: Gas compressor pressure regulation.

13.Filling Manifold: split high-pressure oxygen & nitrogen into each gas cylinder.

CONTACT US:

Email: Lyan.ji@hznuzhuo.com

Tel: 0086-18069835230

Alibaba: https://hzniuzhuo.en.alibaba.com